Milk cooling system «Rodnik» of our production

Designed for collecting and cooling milk from robotic milking machines

- Starts operation with the first drops;

- Suitable for any milking robot;

- The price is much lower than that of import analogues.

Installation summary

Fullwood M²erlin

- 17 years of experience in the field of robotic milking systems

- Special milking technology

- In-house design and production

- World markets

- Technology of the future

What’s new?

- Integrated traffic management;

- Brand new, almost silent manipulator;

- New milking box suitable for all breeds of cows and their conformation;

- Reduced power consumption;

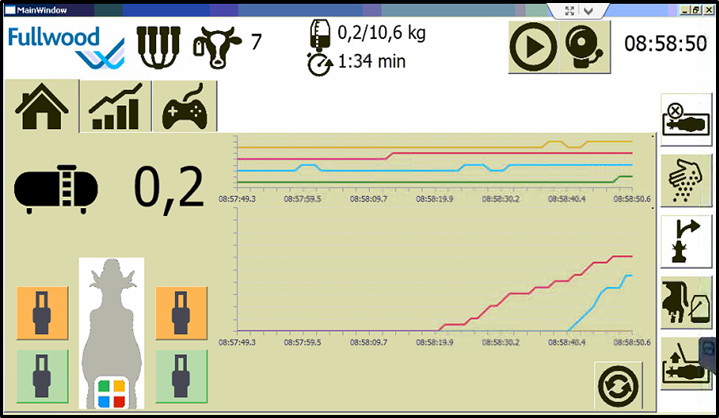

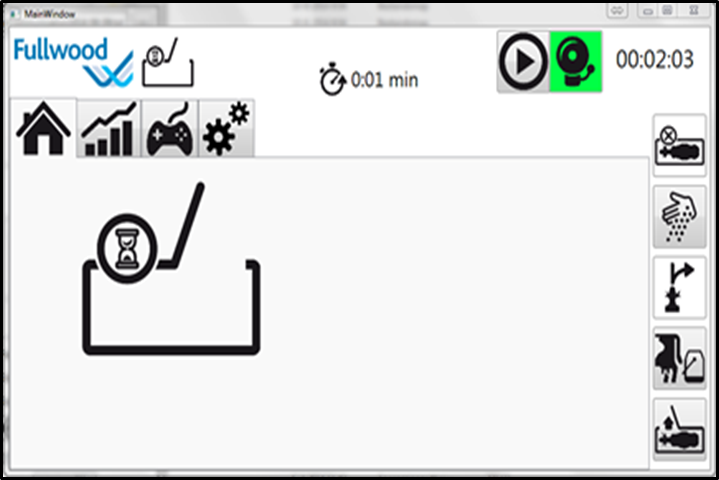

- New multi-function touch screen with IPUS;

- Full compatibility with previous and future Merlin robots;

- MerlinView control panel to display all key indicators;

- Comes in 3 basic versions and with additional options.

Main functions

1) Input of cows;

2) Identification of animals;

3) Making a decision – to milk or not;

4) Milking.

Milking system features

- Feed supply;

- Preparation of dugs;

- Milking, pure milk is fed into the tank;

- Milking, substandard milk is discarded;

- Treatment of dugs after milking;

- The cow is sent back to the group or to the breeding zone.

Fullwood M²erlin robots are available as both left- and right-sided models

Left-sided

As seen from the clean zone of the M²erlin installation, the cow’s head is on the left

Right-sided

As seen from the clean zone of the M²erlin installation, the cow’s head is on the right

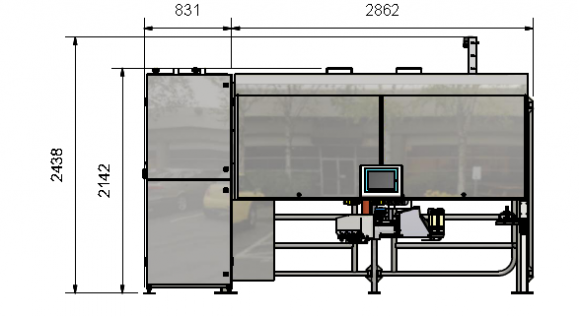

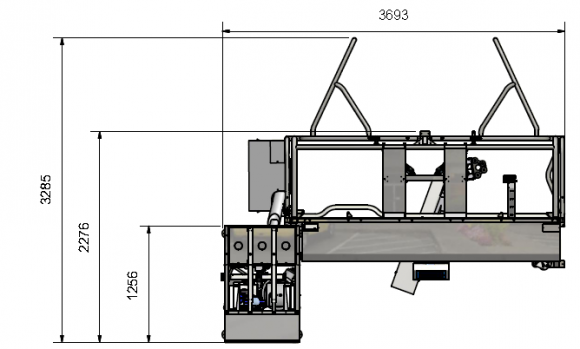

Fullwood M²erlin parameters

Length: 3693 mm

Width: 3285 mm

Height: 2348 mm

Weight: 1200 kg

Brand new manipulator

- New motor for the dugs preparation brush;

- Fast reconnection of teat cups;

- 6 options for dugs rubber to ensure optimal fit of teat cups on the udder of any cow;

- Straining and discarding of first trickles.

Vacuum and milk flow sensors / blocking valves – fully sealed for optimum protection

New milking box

- Suitable for any breeds of cows;

- Open, spacious and comfortable;

- Suitable for milking cows of any size;

- Video camera for cow positioning;

- The increased amplitude of movement of the manipulator compared to the previous model:

- More than 40 mm in the lower position;

- More than 50 mm in the upper position.

Low power and water consumption

The energy required to move the manipulator is significantly reduced compared to systems using compressed air (more than a 50% reduction)

The Merlin installation consumes 80-120 liters of water per sink (depending on the length of the feeding milk line)

Low friction bearings on all moving parts to reduce power consumption

Minimal use of pneumatic equipment to reduce energy and air consumption

IPUS

Livestock Management Program Interface

- User-friendly touch screen for manual adjustment of operation on the robot;

- Intuitive control via the interface using icons;

- Information center providing an excellent overview;

Key commercial features

- Integrated traffic management;

- First-class comfort and safety levels for cows;

- Brand new, almost silent manipulator system;

- Excellent speed of connecting the device and milking;

- High-performance machine;

- Significant reduction in energy consumption;

- Touch intuitive IPUS interface;

- Merlin View / Crystal. The most comprehensive management system;

- It is easily adapted both to new cowsheds and to old ones.

RU

RU